Category: General

What Is Custom Converting? An overview for Manufacturers, Designers & Engineers

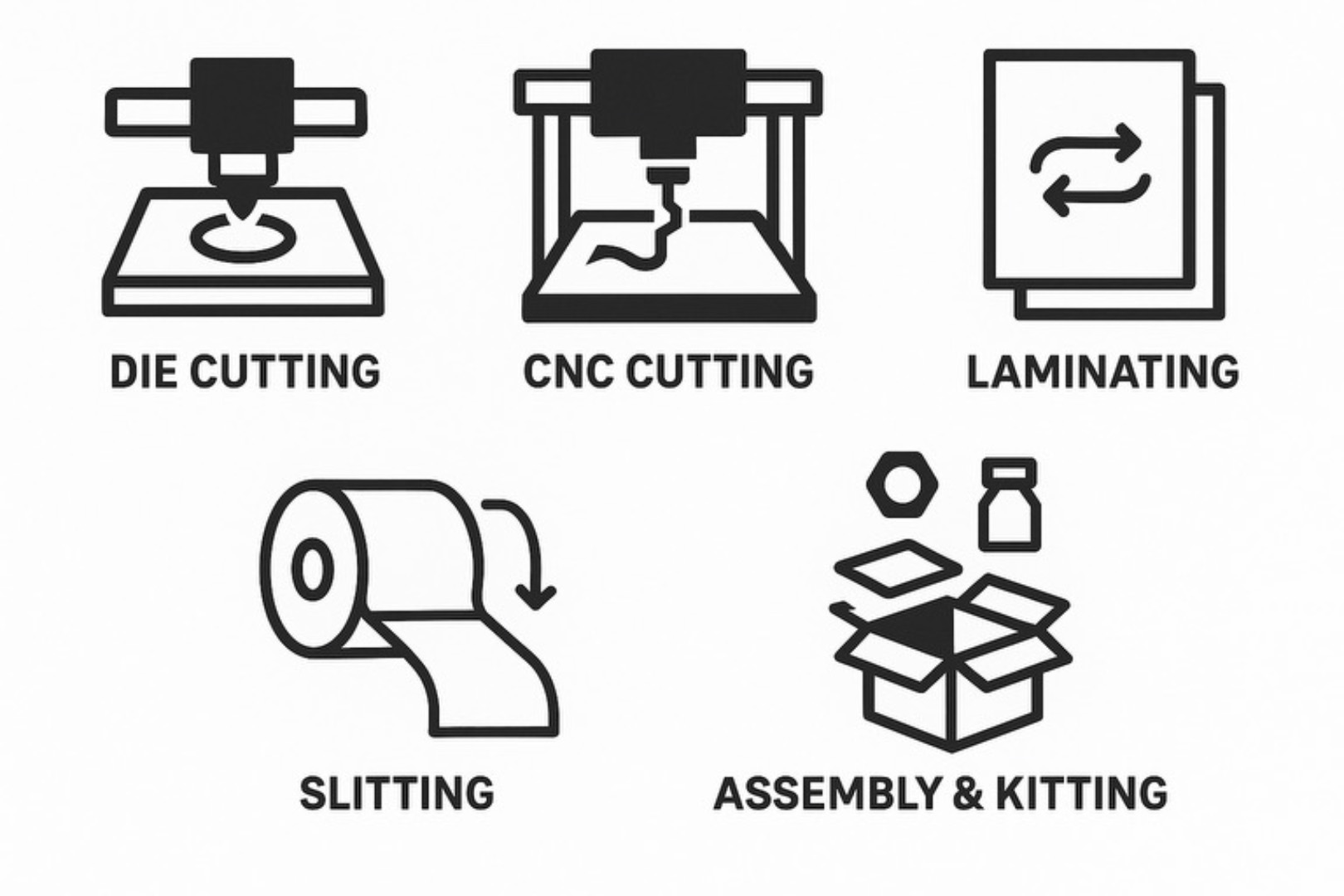

What Is Custom Converting? Custom converting is the process of transforming raw materials—like foam, felt, rubber, nonwoven fabrics, and adhesive-backed substrates—into precise components that meet specific shape, size, and performance requirements. From gaskets and filter pads to packaging inserts and assembly components, converting brings material solutions to life for a range of industries. At Dott Products, we’re a vertically integrated custom converter, which means we handle the entire process in-house—from material sourcing and design to cutting, laminating, and packaging. This full-service approach leads to faster turnarounds, greater control over quality, and increased flexibility for prototyping and production. Our Core Converting Capabilities Die Cutting: Flatbed and rotary options for high precision and high-volume production. CNC Cutting: Ideal for complex shapes, tight tolerances, and short-run production. Laminating: Bonding multiple materials or adhesives for performance or assembly ease. Slitting: Cutting wide rolls into narrow widths for spooling or further processing. Assembly & Kitting: Creating multi-component assemblies or packaging kits. Prototyping: Rapid testing and development for new product designs. Why Choose a Custom Converter Like Dott? Choosing Dott Products gives you access to decades of experience, deep material knowledge, and flexible manufacturing solutions tailored to your exact needs. Rather than adaptin

Choosing the Right Material for Your Gasket, Insert, or Filter: Foam vs. Felt vs. Nonwoven

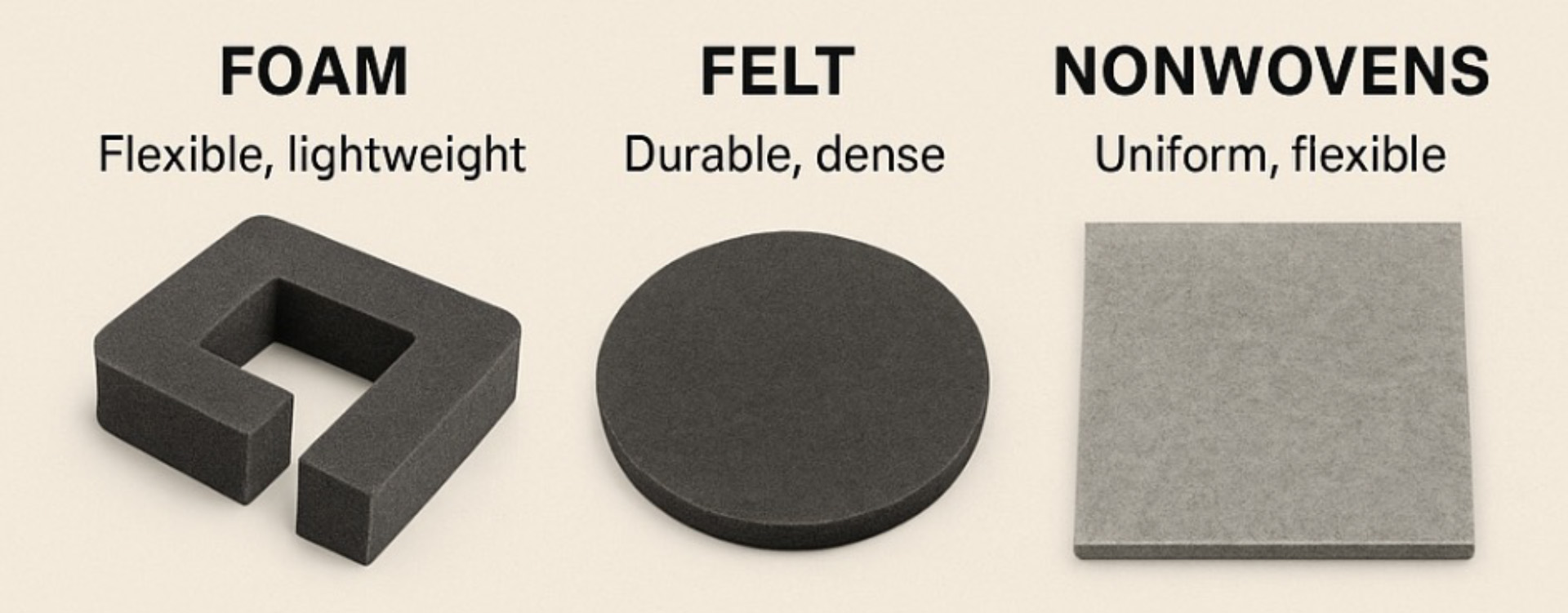

When it comes to performance-critical components like gaskets, filters, and inserts, material selection is everything. At Dott Products, we work with a wide range of industrial substrates—helping customers choose the right material for their specific sealing, filtering, or cushioning needs. In this post, we’ll break down three of the most common materials we convert: foam, felt, and nonwovens. Material Types Overview Foam: Flexible, lightweight, and available in a variety of open- and closed-cell configurations, foam is widely used in gasketing, insulation, and packaging applications. Urethane, polyurethane, polyethylene, and EVA foams each offer unique compression, rebound, and resistance properties. Felt: Known for its durability and density, felt is often used in noise dampening, vibration control, and filtration. Industrial felt can be made from natural fibers like wool or synthetic blends and offers excellent wear resistance in high-friction environments. Nonwoven Materials: Made by bonding fibers together through chemical, mechanical, or thermal processes, nonwovens offer uniformity and flexibility. These materials are especially common in air and liquid filtration, medical components, and disposable consumer products. Choosing Based on Application The key to successful material selection is aligning your choice with the function of the part: Sealing: Closed-cell foam offers excellent resistance to moisture and air penetration. Filtering: Nonwoven po